Introduction

The complex topic of sustainability has many facets within it.

Being sustainable means not only using the right energy resources, but also making the most of them by increasing one’s efficiency. This implies making maximum use of the energy source at one’s disposal to reap the maximum benefit.

Renewable energy technologies today have made great strides and are increasingly important in reducing the environmental footprint. Such resources, however, are often characterized by low efficiency. Just think, for example, of photovoltaic systems whose efficiency is estimated to be around 15-20%.

To overcome the problem of thermal waste and increase the efficiency of one’s business, it is necessary to implement special technologies capable of recovering energy that would otherwise be dissipated: ORC systems.

This technology, which also makes the most of low-temperature heat flows, makes use of a special turbine that provides not only improved efficiency. In fact, some of its main advantages are also reducing its environmental footprint by reducing the release of CO2 into the atmosphere, and producing electricity.

Technology

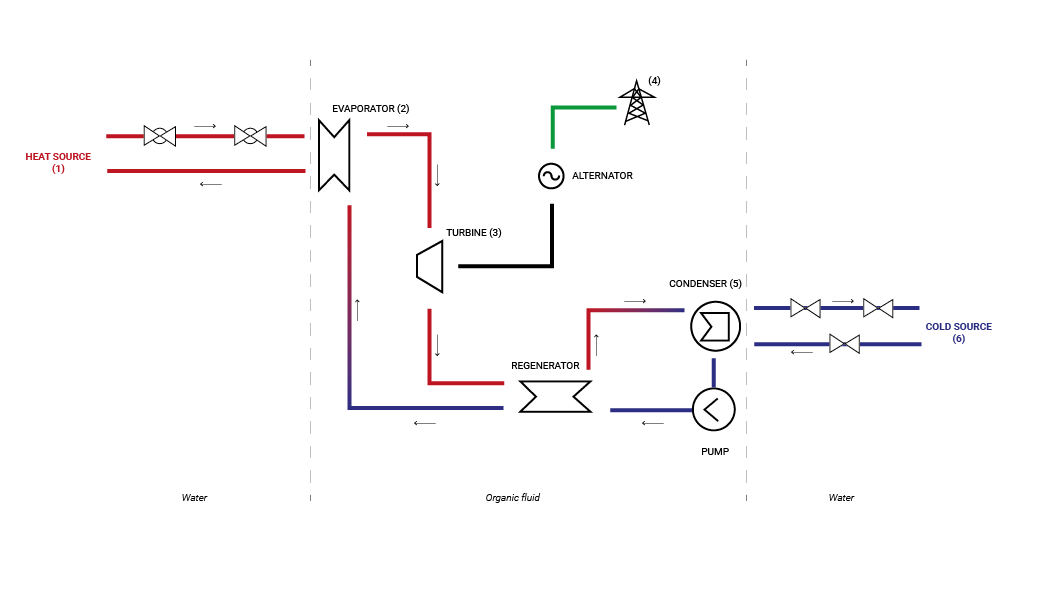

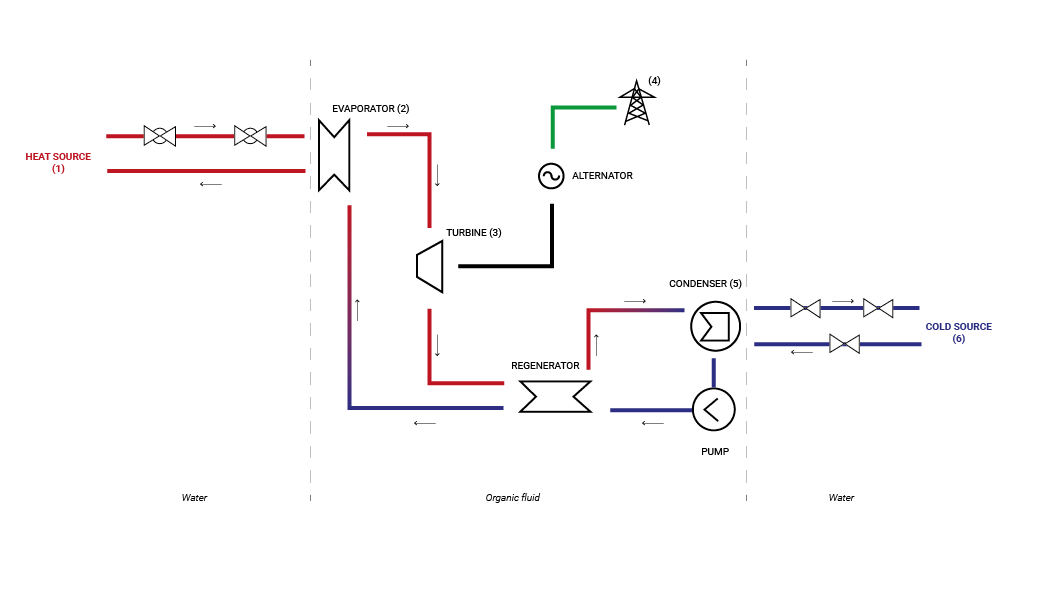

- A heat source [1] heats a carrier fluid (water or, in larger systems, thermal oil) circulating in a closed circuit. The carrier fluid conveys the absorbed heat to one or more primary heat exchangers, usually a preheater and an evaporator [2], where the heat is transferred from the carrier fluid to the working fluid.

- The fully biodegradable and environmentally friendly organic fluid is put under pressure by a pump [7] and sent to the exchanger-evaporator, where it is transformed, as it expands, from a liquid into a vapor.

- The organic fluid in the form of vapor, expanding, drives the Turbine[3] to whose shaft the rotor of an alternator is attached. The high-speed rotation (12,000÷18,000 Rpm) of the turbine will, once driven, generate electricity.

- The working fluid, still in the gaseous phase, is conveyed inside the condenser [5], where it is cooled by releasing its excess heat. Collected within a condenser tank, the working fluid is thus ready to be fed back into the system through a recycle pump, thus closing the cycle.

- The excess heat released into the condenser itself represents a source of low-temperature thermal energy that can be used for other purposes such as preheating or drying fuel biomass to increase its heating value, heating buildings, producing hot water, and so on. In case there is no way to employ it, the waste heat can be dissipated through an external cooling system (dry cooler) [6].

Application

The Organic Rankine Cycle, operating at low temperatures, lends itself excellently to the realization of heat recovery systems.

The sectors in which this technology finds application, providing different benefits, are diverse:

- Heat Recovery from Industrial Processes: ORC systems can recover waste heat from various industries such as paper, cement, glass, ceramics, and steel. Operating at low temperatures, the Organic Rankine Cycle, lends itself excellently to thermal recovery, , enhancing hitherto unnecessarily wasted thermal waste.

- Geothermal: Geothermal energy is a form of renewable energy derived from the earth’s internal heat. By inserting a thermal collection system into an existing hot spring or by injecting cold water into an ad hoc borehole drilled at appropriate locations on the earth’s surface, a flow of water with a high enough flow rate and temperature to drive one or more ORC systems can be obtained.

- Solar Thermodynamic: ORC systems lend themselves easily to the realization of solar thermodynamic or hybrid systems, due in part to their excellent performance under partial load-that is, when the thermal energy is below nominal specification values. Such systems are able to harness the relatively low temperature heat obtained from simple concentrating solar thermal panels as long as it is available. Hybrid systems can then switch automatically to the exploitation of alternative thermal sources (biomass or biogas boilers, geothermal heat….) if solar production is insufficient, such as at night or in inclement weather.

- Recovery from Engines: ORC modules, enhancing the low temperatures at which they operate, are an excellent choice for heat recovery from the most varied types of engines and generators (gensets) to which they can be safely and effectively interfaced through a simple closed circuit with hot or superheated water that guarantees efficiency, safety and plant engineering simplicity.

Advantages

Thermal recovery systems through ORC cycle, due to their technology provide a number of advantages:

- They enhance low-temperature thermal flows that would otherwise be lost

- They are applicable to different thermal sources (superheated acuqa, flue gas, etc.)

- They increase the efficiency of the systems in which they are installed

- They reduce the level of CO2 released into the atmosphere

- Reduce energy costs by producing electricity